-

HENGKO® Nadiifinta Sare ee Semiconductor Gaas Filter

filtarrada taxanaha daahirsanaanta sare waxaa loogu talagalay in lagu shaandheeyo gaaska semiconductor.Kulankaan si buuxda alxanka leh ayaa keenaya sii haynta 0.003 micron qayb ka mid ah oo la caawiyey.nus...

Daawo Faahfaahin -

Shaandheeyaha gaaska birta ee khadka dhexda ah ee dhexda ah ee nidaamka nadiifinta gaaska Semiconductor

Shaandheeyayaasha gaaska birta ee khadka dhexda ku jira ayaa ka shaqeeya sidii ay u saari lahaayeen wasakhda ay ku jiraan qoyaanka, ogsijiinta, kaarboon laba ogsaydh, kaarboon monoksaydh, kaarboon-carbon iyo kaarboonyl-yada birta

Daawo Faahfaahin -

HENGKO Nadiifinta Sare ee Sare ee Qolka birta Diffusers Dhagaxa sifeynta gaaska saafiga ah ee sare ...

HENGKO Diffusers Metal Porous si dhakhso ah ayey qolalka faakuumka hawada ugu sii daayaan taasoo hoos u dhigaysa wakhtiga wareegga oo kordhisa wax soo saarka.Qalabkayaga birta aan lahayn

Daawo Faahfaahin -

Dareemka heerkulka iyo qoyaanka ee Semiconductor Nadiifi heerkulka qolka qoyaanka Contr...

Bandhiga Alaabta Heerkulka iyo huurka meel nadiif ah waxaa inta badan lagu go'aamiyaa iyadoo loo eegayo shuruudaha nidaamka, laakiin waxay hoos imaanayaan shuruudaha buuxinta...

Daawo Faahfaahin -

Sintered SS 316L ahama birta aan ololka lahayn ee ilaalinta shaandhada guryaha warshadaha

Isku-xidhaha dareemayaasha aan qarxin waxay ka samaysan yihiin 316 bir ah oo aan lahayn si loo ilaaliyo daxalka ugu badan.Xir-xiriyaha ololka isku xiran wuxuu bixiyaa faafinta gaaska...

Daawo Faahfaahin -

316L shaandhada shaandhada ololka-cadeynta ah ee guryaha co2 semiconductor microns modbus filter filter filter ho...

Guryaha dareemaha qarxa ee HENGKO waxay ka samaysan yihiin 316L ahama iyo aluminium si loogu ilaaliyo daxalka ugu badan.Dab-qabtaha ololka isku xidhan wuxuu bixiyaa...

Daawo Faahfaahin

Shaandheeyayaasha gaaska Semiconductor:

Hubinta Nadiifnimada Gaaska Aan Fiicneyn ee Chipmaking

Dunida qalafsan ee wax soo saarka semiconductor, halkaas oo saxnaanta iyo nadiifnimada ay ugu muhiimsan yihiin, tayada

Gaasaska la isticmaalo ayaa door muhiim ah ka ciyaara go'aaminta guusha habka.Najaasaha, xitaa heerar aan dhammaad lahayn,

waxay wax u dhimi kartaa wareegga jilicsan ee microchips, taasoo ka dhigaysa mid cilladaysan oo aan la isticmaali karin.Si loo ilaaliyo

Nidaamkan xasaasiga ah, filtarrada gaaska semiconductor waxay u taagan yihiin ilaalo aan adkaysan, si taxadar lehna uga saaraya wasakhda

iyo hubinta tayada saafiga ah ee gaaska ku qulqulaya khadadka wax soo saarka.

Waxaa jira sifooyin badan oo aad u fiican iyo faa'iidooyinka filtarrada birta ah ee sintay

1. Lagu farsameeyay Deegaanka Nadiifinta ee Casriga ah

Shaandhooyinkani waxay ku dhasheen qol nadiif ah oo casri ah, deegaan si taxadar leh loo ilaaliyo xaaladaha aan wanaagsanayn si loo yareeyo wasakhda kasta oo iman karta.Waxay marayaan hab wax-soo-saar adag, oo ka bilaabmaya alxanka saxda ah ee hoos yimaada jawiga hawo nadiifsan.Biyo nadiifinta ka dib, oo ay ku xigto cadaadis sare, nadiifinta nitrogen ee la sifeeyay, waxay tirtirtaa wax kasta oo walxaha daahaya waxayna yaraynaysaa khatarta daadinta walxaha.

2. Waxtarka Kasaarida Walxaha Gaarka ah

Iyada oo hufnaanta sifeynta cajiibka ah ee 9 LRV ee qaybaha 0.003μm, u hoggaansanaanta heerarka adag ee ay dejiyeen hababka tijaabada SEMI F38 iyo ISO 12500, filtarradani waxay si wax ku ool ah uga saaraan wax kasta oo walxaha daxalka ka soo baxa iyo walxaha ka soo baxa qaybaha dhaqaaqa, iyagoo hubinaya nadiifnimada saafiga ah ee xuubka gaasaska.

3. Xoogga Makaanikada Sare

Si adag loo tijaabiyay si loo dammaanad qaado adkeysiga gaarka ah ee dalbanaya hababka wax soo saarka iyo bay'ada inta badan isticmaala cadaadiska gaaska sare, filtarradani waxay bixiyaan waxqabad aan leexleexad lahayn inta ay nool yihiin.

4. Ka-dhaafitaanka Heerarka Warshadaha ee ugu sarreeya

Ka gudubka shuruudaha shaandhaynta gaaska adag ee maaraynta gaaska ee farsamaynta semiconductor, filtarradani waxay maraan tijaabo adag si loo dammaanad qaado inay la kulmaan hufnaanta sifaynta muhiimka ah, xakamaynta socodka saxda ah, iyo heerarka badbaadada ee ay dalbadaan nidaamyada gaaska gaaska ee wax soo saarka semiconductor.

5. Ballanqaadka Badbaadada oo aan leexleexad lahayn

Si looga ilaaliyo soo-gaadhista gaasaska gubanaya, daxalka, sunta ah, iyo hab-socodka pyrophoric, guryaha shaandhada waxa la mariyaa tijaabinta daadinta, hubinta inay gaadhaan heerka daadinta cajiibka ah ee ka yar 1x10-9 atm scc/second.Ballanqaadkan aan leexleexa lahayn ee badbaadada ayaa hubinaysa in gaasaska khatarta ah ay ku jiraan lagana ilaaliyo inay waxyeello geystaan.

6. Nadaafad aan liidasho lahayn oo loogu talagalay Chipmaking Heer sare

Iyada oo loo marayo awoodahooda sifaynta gaarka ah, ballanqaad aan leexleexad lahayn xagga amniga, iyo u hoggaansanaanta heerarka warshadaha ugu sarreeya, filtarrada gaasku waxay door muhiim ah ka ciyaaraan ilaalinta hannaanka qallafsan ee wax-soo-saarka semiconductor.Waxay u taagan yihiin ilaalinta nadaafadda, iyagoo hubinaya in kaliya gaasaska ugu nadiifsan ay ku qulqulayaan khadadka wax soo saarka, iyaga oo u gogol xaaraya abuuritaanka microchips-ga sarreeya ee awood u leh adduunkeena casriga ah.

Noocyada filtarrada Semiconductor

filtarrada Semiconductor waxaa loo isticmaalaa codsiyo kala duwan, oo ay ku jiraan:

* Soo saarista Elektrooniga:

filtarrada Semiconductor waxaa loo isticmaalaa in laga saaro walxaha biyaha ultrapure, gaasaska, iyo kiimikooyinka loo isticmaalo soo saarida semiconductors.

* Qorshaynta farsamaynta kiimikaad (CMP):

filtarrada Semiconductor waxaa loo isticmaalaa in laga saaro qaybaha CMP slurries, kuwaas oo loo isticmaalo in lagu nadiifiyo maraqyada semiconductor.

* Dhakhtarka noolaha:

filtarrada Semiconductor waxaa loo isticmaalaa in laga saaro qaybo ka mid ah dareerayaasha loo isticmaalo ogaanshaha iyo daawaynta caafimaadka.

* Deegaanka:

filtarrada Semiconductor waxaa loo isticmaalaa in laga saaro walxaha hawada iyo biyaha.

Waxaa jira afar nooc oo waaweyn filtarrada semiconductor:

1. Shaandhooyinka xuubabka:

Shaandhooyinka xuubka waxay ka samaysan yihiin filim khafiif ah, oo dalool leh oo u oggolaanaya dareeraha inay dhex maraan marka ay dabinayaan qaybaha.

2. Shaandhaynta qoto dheer:

Shaandheeyayaasha qoto-dheer waxay ka samaysan yihiin sariir qaro weyn, dildilaacsan oo walxo ah oo dabinaysa walxaha marka ay dhex qulqulayaan shaandhada.

3. filtarrada adsorbent:

Shaandhada adsorbent waxay ka samaysan yihiin shay soo jiidanaya oo xajiya qaybaha.

4. Shaandhooyin bir ah oo sintay

Shaandhooyinka birta la jeexjeexay waa nooc ka mid ah shaandhada qoto-dheer ee sida caadiga ah loo isticmaalo wax soo saarka semiconductor.Waxa lagu sameeyay in budo bir ah oo khafiif ah loo geliyo qaab daloola.Shaandhooyinka birta ah ee la jeexjeexay waxaa lagu yaqaanaa adkeysigooda sare, hufnaanta sifeynta sare, iyo awoodda u adkeysiga heerkulka sare iyo cadaadiska.

Faa'iidooyinka filtarrada birta sintered ee wax soo saarka semiconductor:

* adkeysiga sare:

* Waxtarka sifaynta sare:

* Cimri dheer:

* Waafaqid kiimikaad:

Codsiyada filtarrada birta sintered ee wax soo saarka semiconductor:

* Nadiifinta gaasta:

Shaandhooyinka birta ah ee la jeexjeexay ayaa ah qayb muhiim ah oo ka mid ah habka wax-soo-saarka semiconductor, iyagoo gacan ka geysanaya hubinta soo-saarka aaladaha semiconductor tayo sare leh.

Nooca filtarrada semiconductor ee loo isticmaalo codsi gaar ah waxay kuxirantahay cabbirka qaybaha la saarayo, nooca dareeraha la sifeynayo, iyo heerka shaandhaynta ee la doonayo.

Halkan waxaa ah shax soo koobaya noocyada kala duwan ee filtarrada semiconductor:

| Nooca shaandhaynta | Sharaxaada | Codsiyada | Sawirka |

|---|---|---|---|

| filtarrada xuubabka | Waxaa laga sameeyay filim dhuuban, dalool leh oo u oggolaanaya dareeraha inay dhex maraan marka ay dabinayaan walxaha. | Soo saarista elektiroonigga ah, CMP, biomedical, deegaanka | |

| Shaandhaynta qoto dheer | Waxa laga sameeyay sariir qaro weyn, dildilaacsan oo walxo ah oo dabinaysa walxaha marka ay dhex qulqulayaan shaandhada. | CMP, biomedical, deegaanka | |

| filtarrada adsorbent | Ka samaysan shay soo jiidanaya oo xajiya qaybaha. | Soo saarista elektiroonigga ah, CMP, biomedical, deegaanka | |

| Shaandhooyin bir ah oo la shiiday | Lagu sameeyay iyada oo la miiray budo bir ah oo fiican oo laga dhigay qaab-dhismeed dalool ah. | Nadiifinta gaasta, sifaynta kiimikaad, sifaynta biyaha ultrapure, sifaynta dareeraha CMP | Shaandhooyin bir ah oo la shiiday oo loogu talagalay semiconductor |

Codsiga

Shaandheeyayaasha gaaska semiconductor birta sintered ayaa si weyn loogu isticmaalaa codsiyada kala duwan ee warshadaha semiconductor.Sifooyinkooda gaarka ah, sida hufnaanta sifaynta sare, adkeysiga, iyo awoodda u adkeysiga heerkulka sare iyo cadaadiska, waxay ka dhigaan qayb muhiim ah oo ka mid ah nidaamyada gaaska gaaska ee wax soo saarka semiconductor.

Waa kuwan qaar ka mid ah codsiyada gaarka ah ee filtarrada gaaska semiconductor-ka birta ah ee sintay:

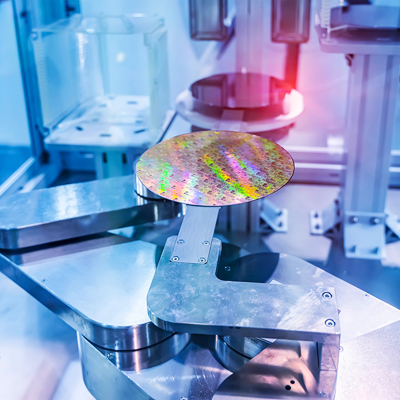

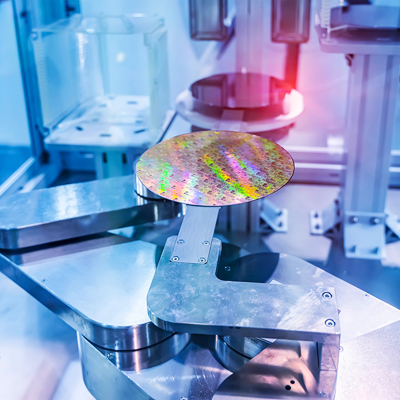

1. Wax soo saarka Wafer:

Shaandhooyinka birta la shiiday waxaa loo isticmaalaa in lagu nadiifiyo gaaska loo isticmaalo soosaarka waferka, sida nitrogen, hydrogen, iyo oxygen.Gaasaskani waxay lama huraan u yihiin hababka sida koritaanka epitaxial, etching, iyo doping.

2. Sifeynta kiimikada:

Shaandhooyinka birta la shiiday waxaa loo isticmaalaa in lagu shaandheeyo kiimikooyinka loo isticmaalo wax soo saarka semiconductor, sida asiidhka, saldhigyada, iyo dareerayaasha.Kiimikooyinkan waxaa loo isticmaalaa ujeeddooyin kala duwan, oo ay ku jiraan nadiifinta, xoqidda, iyo nadiifinta.

3. Sifeynta biyaha Ultrapure:

Shaandhooyinka birta ah ee la jeexjeexay ayaa loo isticmaalaa in lagu shaandheeyo biyaha ultrapure (UPW) ee loo isticmaalo wax soo saarka semiconductor.UPW waxay lagama maarmaan u tahay nadiifinta iyo luqluqashada maraqa, iyo sidoo kale diyaarinta kiimikooyinka.

4. Sifeynta dareeraha CMP:

Shaandhooyinka birta ah ee la jeexjeexay ayaa loo isticmaalaa in lagu shaandheeyo CMP slurries, kuwaas oo loo isticmaalo in lagu nadiifiyo weelasha semiconductor.CMP waa geeddi-socod muhiim ah oo lagu soo saaro microchips.

5. Sifeynta barta-isticmaalka (POU):

Shaandhooyinka birta ah ee la jeexjeexay ayaa badanaa loo isticmaalaa sida filtarrada POU, kuwaas oo si toos ah loogu rakibay goobta isticmaalka si loo bixiyo heerka ugu sarreeya ee sifeynta.Shaandhooyinka POU ayaa si gaar ah muhiim ugu ah codsiyada halka ay nadiifinta gaasku muhiim u tahay, sida soo saarista microprocessors iyo aaladaha kale ee waxqabadka sare leh.

6. Maareynta gaaska saafiga ah oo sarreeya:

Shaandhooyinka birta ah ee la jeexjeexay ayaa loo adeegsadaa nidaamyada maaraynta gaaska nadiifka ah ee sarreeya si looga saaro wasakhda gaasaska loo isticmaalo soosaarka semiconductor.Wasakhayntan waxaa ka mid noqon kara qaybo, qoyaan, iyo isku-dhisyo dabiici ah.

7. Wax-soo-saarka Microelectronics:

Shaandhooyinka birta ah ee la jeexjeexay ayaa loo adeegsadaa soo saarista microelectronics, sida kombuyuutarrada, tablet-yada, talefannada gacanta, dareemayaasha IoT, iyo qalabka xakamaynta.

8. Sifeynta nidaamyada-kaanigga-yar ee elektiroonigga ah (MEMS):

Shaandhooyinka birta ah ee la jeexjeexay ayaa loo isticmaalaa sifaynta MEMS, taas oo ah habka looga saarayo wasakhda hababka elektro-electromechanical-yar.MEMS waxaa loo isticmaalaa codsiyo kala duwan, oo ay ku jiraan dareemayaasha, hawlgeliyayaasha, iyo transducers.

9. Sifeynta qalabka kaydinta xogta:

Shaandhooyinka birta ah ee la jeexjeexay ayaa loo isticmaalaa sifaynta aaladaha kaydinta xogta, taas oo ah habka looga saarayo wasakhda aaladaha kaydinta xogta, sida darawallada adag iyo kuwa adag.

Marka lagu daro codsiyadan gaarka ah, filtarrada gaaska semiconductor-ka birta ah ayaa sidoo kale loo isticmaalaa codsiyo kale oo kala duwan oo ku jira warshadaha semiconductor.Kala duwanaanshahooda iyo isku halaynta ayaa ka dhigaya qalab lagama maarmaan u ah soosaarayaasha semiconductor.

Ma waxaad raadineysaa filtarrada gaaska semiconductor-ka birta ah ee tayada sare leh?

HENGKO waa rafiiqaaga si aad u hesho xalalka OEM ee nidaamyada wax soo saarka semiconductor.

Shaandhooyinkeena saxda ah ee loo farsameeyay waxay xaqiijinayaan isku halaynta iyo hufnaanta hababkaaga, iyagoo ku siinaya geeska suuqa tartanka.

Maxaad u doorataa filtarrada HENGKO?

* Tayada sare iyo cimri dhererka

* xalal la habeeyey oo ku habboon baahiyahaaga gaarka ah

* Waxqabadka la xoojiyey ee wax soo saarka semiconductor

Ha u ogolaan caqabadaha sifaynta inay dib u dhigaan wax soo saarkaaga.

Nala soo xiriir maanta si aad u sahamiso sida filtarradayada birta ah ee sintay ay wax uga beddeli karaan nidaamkaaga wax soo saarka.

Nagala soo xidhiidhka@hengko.com

La wadaag HENGKO oo qaado tillaabo aad ugu wanagsan tahay wax soo saarka semiconductor!