-

Soo saaraha Shaandheeyaha Shaydhiyaha Shaydhiyaha Dabada-Dhiga ah ee khadka dhexda ah -HENGKO

HENGKO waxay u soo saartaa weelasha firaaqada ah ee Venus, Kitty, Class, iyo dheryaha Musa Moka. Xirmada waxaa ku jira weel iyo saxan filter kafeega. Dhexroorka gaaska Fadlan...

Daawo Faahfaahin -

Biraha birta ah ee 316L ee birta ah ee gaarka ah waxay u adkaysataa dhululubo shaandhada hawada heerkulka sare ...

Sharaxaad ka bixi sheyga shaandheynta birta aan lahayn ee HENGKO waxaa lagu sameeyay iyadoo la isku xirto 316L walxo budo ah ama mesh bir ah oo badan oo ah mesh silig bir ah oo heerkul sare leh

Daawo Faahfaahin -

HENGKO sintered birta aan fiicnayn 316L miiraha birta-hawo-mareenka koobabka shaandhada iyadoo la adeegsanayo wax 3d ...

Sharaxaad ka bixi sheyga shaandheynta birta ah ee HENGKO waxaa lagu sameeyay iyadoo la isku xirto 316L walxo budo ah ama mesh bir ah oo kala duwan

Daawo Faahfaahin -

bir bir ah oo aan lahayn bir aan lahayn 316L naxaas ah sifaynta hawo nadiifinta dhululubo/shumac

Soo bandhigida filtarrada shumaca ee HENGKO: Xalka Ku-habboon ee Baahiyaha Shaandheynta Warshadahaaga! Astaamaha Alaabta:- Sifeynta ugu Fiican: Shamacayada shamacadeena waa ...

Daawo Faahfaahin -

Koobabka biraha daloola ee daloola waxa ay shaandheeyaan qaabka bamka biyo-xidheenka ah, birta birta ah 60-90 mic...

Sharaxaadda Alaabta HENGKO Shamaca shaandhada sinta leh iyo kartoonada waa shaandhooyin cylindrical ama koofiyad u qaabaysan oo marmarka qaarkood loo yaqaan koobabka filtarrada sintered, kuwaas oo...

Daawo Faahfaahin -

Beddelka Micron sinteed ahama birta dalool saxan filter biraha

Soo bandhigida HENGKO's Tayada Sare ee Birta Aan-Aabaha ahayn ee Shaandheeyayaasha Birta Dabada leh ee HENGKO waa soo-saare hormuud u ah birta daloosha ee birta aan-dhalatada lahayn ee f...

Daawo Faahfaahin -

D6.1*H1.6 20um sintered bir daloolin ah saxan filter bir ahama

Soo bandhigida HENGKO Saxeexa Shaandheynta Sintered: Sii daaya Awoodda Sifeynta Saxda ah! Ma waxaad raadinaysaa saxan filter sintered oo bixiya wax ka baxsan...

Daawo Faahfaahin -

Dalab gaar ah 30-45/50-60um sintered ahamaama koob filtar oo leh iskutallaab t...

HENGKO waxay soo saartaa walxaha shaandhada ee agabyo kala duwan, cabbirro, iyo qalabyo si ay si sahal ah loogu qeexo astaamaha iyo qaabaynta

Daawo Faahfaahin -

30-45/50-60um birta aan dabada lahayn ee birta shaandhaynta ah

Dab-dejiyaha ololku waa qalab ku rakiban furitaanka xero, ama tuubooyinka isku xidha ee nidaamka xidhitaanka. Waxay u ogolaadaan gaas ama uumi inay...

Daawo Faahfaahin -

D9.5*H9.5 60-90um saxan shaandhaynta birta dabada leh ee loo isticmaalo sifaynta dareeraha

Soo bandhigida filtarrada HENGKO sintered disc, xalka ugu dambeeya ee dhammaan baahiyahaaga sifaynta! filtarradayada disc-ka sinteed waxaa loogu talagalay inay dabin adag u dhigaan qayb adag...

Daawo Faahfaahin -

Qalabka filter filter bir aan lahayn alaab-qeybiyaha beddelka microns-ka budada birta ah ee porosity-ka

Saxanadaha Biraha Daloola ee Daloola. oo la mid ah isbuunyo bir ah. Shaandhooyinka birta Sintered ee daloola waxay ka kooban yihiin lebbis heersare ah, shabakado isku xidhan oo daldaloollo ah oo leh toor...

Daawo Faahfaahin -

Walxaha shaandhada budada ah ee la jeexjeexay/koobadaha shaandhaynta birta ee daloolka leh

HENGKO tuubooyinka filter-ka-soo-baxa birta-la'aanta ah waxaa lagu sameeyaa iyadoo la isku dhejiyo 316L walxo budada ah ama mesh silig bir ah oo badan oo heerkul sare leh. Waxay ahaayeen w...

Daawo Faahfaahin -

Saxanka mesh birta-lakab-badan leh ee daahyada ka samaysan

saxan bir ah oo bir ah oo loogu talagalay sariirta dareeraha ah Xakamaynta qaybinta gaaska, gudbinta walxaha budada ah, iyo hawlgalka dareeraha ayaa si weyn loogu isticmaalay indu ...

Daawo Faahfaahin -

shaandhada shaandhada birta ah ee aan birta lahayn ee mikron dalool leh

filtarrada birta ah ee jeexjeexan iyo tuubooyinka daloolku waa dheer yihiin, filtarrada cylindrical oo leh darbiyo dhuuban, tusaale ahaan waxay leeyihiin cabbir dherer ilaa dhexroor sare leh. Shayga birta daloolsan...

Daawo Faahfaahin -

Tusaalaha Tusaalaha Nidaamka Baadhista Tusaalaha Gaaska Aan-Aamiga Ahayn

Baarayaasha muunada gaaska ee HENGKO waxay u isticmaali karaan muunada gaaska joogtada ah ee ka kooban boodhka sare, heerkulka, iyo qoyaanka. Shaandhaynta hordhaca ah: Albaabka laga soo galo...

Daawo Faahfaahin -

316 304 saxan bir ah - Warbaahin shisheeye filter filter bir daloola oo sintered

filtarrada saxan birta ah ee HENGKO waxaa lagu sameeyaa iyadoo la isku dhejiyo 316L walxo budada ah ama mesh birta badan oo aan lakab lahayn heerkul sare. Waxay ahaayeen ...

Daawo Faahfaahin -

Birta daloosha ee ss sinteed disc filter filter oo leh heerka qulqulka degdega ah ee shaandhaynta cabirka yar ee yar...

Soo bandhigida shaandhaynta shaandhaynta ee HENGKO: Sii daaya Awoodda Shaandhaynta Sare! Marka ay timaado sifeynta waxtarka leh, HENGKO's disc sintered filter filter ...

Daawo Faahfaahin -

vacuum KF giraanta cetering leh Sintered Metal Filter

Sharax badeecada Xidhiidhada Flange ee Xarunta dhexda kaga jira shaandhaynta birta sintered ee tignoolajiyada faakuumka waxa loo isticmaalaa ilaa kala duwanaanshaha faakuumka sare ee 10 ilaa -7 mbar...

Daawo Faahfaahin -

Nidaam gaar ah oo sinteering microns ahama birta daloolin koobabka biraha shaandhaynta canaasiirta

HENGKO waxay soo saartaa walxaha shaandhada ee agabyo kala duwan, cabbirro, iyo qalabyo si ay si sahal ah loogu qeexo astaamaha iyo qaabaynta

Daawo Faahfaahin -

Qulqulka qulqulka micron-ka birta aan lahayn budada sintered filter dhululubo

Waxyaabaha filter-ka-soo-baxa ah ee HENGKO waxaa lagu sameeyaa iyadoo la isku dhejiyo 316L walxo budada ah ama mesh birta aan-laabaha lahayn oo heerkul sare leh. Waxay leeyihiin shinni...

Daawo Faahfaahin

Maxaad u doorataa SinteredBirta ShaandhayntaMashaariicda Sifeyntaada:

Shaandhooyin bir ah oo la shiidaywaxaa laga sameeyay budo bir ah oo la riixay oo la miiray (isku darsan) si ay u sameeyaan dalool,

qaab-dhismeed adag. filtarradan waxaa lagu yaqaanaa xooggooda sare, adkeysigooda, iyo awooda ay ku sifeeyaan walxaha aadka u yaryar.

8-da Astaamood ee ugu muhiimsan ee Shaandhooyinka birta la shiiday

HENGKO waxay soo bandhigtaa alaabooyin kala duwan oo shaandhayn bir ah, oo ay ku jiraan birta aan-daawaha lahayn, naxaas la miiray,

shabag jeexjeexan, iyo filtarrada titanium-ka sintered, filtarrada budada birta ah, filtarka birta sinteredsaxanadaha, iyo sintered ahama

birtuubooyinka. filtarradayada waxaa loogu talagalay codsiyada u baahan heerar sare oo ka hortagga daxalka, heerkulka sare,

iyo waxqabadka saxda ah ee sare.

1. Xoog Sare:

Shaandhooyinka birta ah ee la jeexjeexay ayaa laga sameeyaa budada birta ah, taas oo siinaysa awood sare

iyo adkeysiga.

2. Iska caabbinta heerkulka sare:

Shaandhooyinka birta ah ee la shiiday waxay u adkeysan karaan heerkulka sare, iyaga oo samaynaya

ku haboon jawiga heerkulka sare.

3. Iska caabinta daxalka:

Shaandhooyinka birta ah ee la jeexjeexay ayaa u adkaysta daxalka waxaana loo isticmaali karaa daxalka

deegaan.

4. Caabbinta Kiimikada:

Shaandhooyinka birta ah ee la shiiday waxay iska caabiyaan inta badan kiimikooyinka, iyaga oo ka dhigaya kuwo ku habboon kiimikaad

codsiyada habaynta.

5. Waxtarka sifaynta sare:

Shaandhooyinka birta ah ee la jeexjeexay waxay leeyihiin qaab-dhismeed dalool oo aad u fiican, kaas oo u oggolaanaya

si fiican u sifee walxaha aadka u yaryar.

6. Awood haysashada wasakhda sare:

Shaandhooyinka birta ah ee la jeexjeexay ayaa leh awood sare oo wasakh ah, taasoo la macno ah inay awoodaan

shaandhayso xaddi badan oo dareere ah ka hor inta aan loo baahnayn in la beddelo.

7. Si fudud loo Nadiifin karo:

Shaandhooyinka birta ah ee la jeexjeexay si fudud ayaa loo nadiifin karaa oo dib loo isticmaali karaa, taas oo ka dhigaysa mid qiimo leh

mustaqbalka fog.

8. Kala duwanaansho:

Shaandhooyinka birta ah ee la jeexjeexay ayaa lagu samayn karaa qaabab iyo cabbirro kala duwan si loo daboolo baahiyaha gaarka ah

codsiyada kala duwan.

Shaandhooyinka biraha daloolinaya, birta aan la kala saarin ayaa ah doorashada ugu habboon ee lagu sifeynayo farsamaynta kiimikada, sifaynta batroolka,

koronto dhalin, wax soo saarka dawooyinka, iyo codsiyada kale.

Wixii HENGKO, dhammaanxubno filter sinteredmari tijaabo tayo adag ka hor inta aan la dhoofin, oo ay ku jirto hufnaanta sifaynta

iyo indho indhayn. filtarradayada biraha sintered waxay leeyihiin waxtarka saarista walxaha sare, iska caabinta daxalka, ka yar

hoos u dhigista cadaadiska, nadiifinta fudud, iyo faa'iidooyinka dhaqidda dhabarka marka loo eego alaab-qeybiyeyaasha kale ee shaandhada birta ah.

Haddii wax-soo-saarkayada aanu hadda buuxinayn shuruudaha shaandhaynta, fadlannala soo xidhiidhalaabtaada, cabbirkaaga,

iyo baahida codsiga.

CodsigaShaandhaynta SinteredAlaabta

Shaandheeyayaasha sintered ayaa loo adeegsadaa warshado badan oo kala duwan, oo ay ku jiraan farsamaynta kiimikada, sifaynta batroolka, korontadda, iyo soosaarka dawooyinka. Waxay ku habboon yihiin in loo isticmaalo codsiyada halka heer sare oo waxtarka shaandhaynta loo baahan yahay, iyo halka shaandhada ay tahay inay u adkeyso heerkulka sare, cadaadiska, iyo bay'adaha daxalka. Qaar ka mid ah codsiyada ugu caansan ee alaabta shaandhada sintered waxaa ka mid ah:

Sifeynta dareeraha

Shaandhooyinka biraha la jeexjeexay ayaa caadi ahaan loo isticmaalaa sifaynta dareeraha ee warshado kala duwan. Waxay si gaar ah faa'iido ugu leeyihiin codsiyada halka dareeraha la sifeynayo uu yahay viscous ama ay ku jiraan heer sare oo adag. Shaandhooyinka sinta leh waxay ka saari karaan qaybo yaryar sida 1 micron, taas oo ka dhigaysa mid ku habboon in loo isticmaalo codsiyada halkaasoo heer sare oo waxtarka sifaynta looga baahan yahay.

dareere

Shaandhooyinka birta ah ee la jeexjeexay ayaa sidoo kale loo isticmaali karaa codsiyada dareeraha, halkaas oo ay ka caawiyaan inay si siman u qaybiyaan gaaska ama dareeraha sariirta qaybaha adag. Tani waxay si gaar ah faa'iido u leedahay codsiyada sida catalysis, halkaas oo ay muhiim tahay in la hubiyo in dhammaan fal-celiyeyaasha si siman loo qaybiyo.

Sparging

Shaandhooyinka birta ah ee la jeexjeexay ayaa sidoo kale loo isticmaali karaa codsiyada xajinta, halkaas oo ay ka caawinayaan in ay gaaska ku shubaan dareeraha. Tani waxay si gaar ah faa'iido u leedahay codsiyada sida halsano, halkaasoo ay muhiim tahay in la hubiyo in dareeraha la khamiiray uu si wanaagsan u hawo-maray.

Faafin

Shaandhooyinka birta ah ee la jeexjeexay ayaa sidoo kale loo isticmaali karaa codsiyada fidinta, halkaasoo ay ka caawiyaan inay si siman u qaybiyaan gaaska ama dareeraha iyada oo loo marayo xuubka. Tani waxay si gaar ah faa'iido u leedahay codsiyada sida unugyada shidaalka, halkaasoo ay muhiim tahay in la hubiyo in fal-celiyeyaasha ay si siman ugu qaybsan yihiin xuubka.

Qabta Ololka

Shaandhooyinka birta ah ee la shiiday waxa kale oo loo isticmaali karaa dab-qabtayaal ahaan, halkaas oo ay ka caawiyaan ka hortagga fiditaanka ololka ama qaraxyada. Tani waxay si gaar ah faa'iido u leedahay codsiyada sida sifaynta ama dhirta kiimikaad, halkaas oo ay yaaliin walxo guban kara.

Sifeynta Gaaska

Shaandhooyinka birta ah ee la jeexjeexay ayaa sidoo kale loo isticmaalaa sifaynta gaaska ee codsiyada warshadaha kala duwan. Waxay si gaar ah faa'iido ugu leeyihiin codsiyada halka gaaska la sifeynayo uu ku jiro heer sare oo qoyaan ama wasakh kale. Shaandheeyayaasha la jeexjeexay waxay ka saari karaan qaybo yaryar sida 0.1 micron, taas oo ka dhigaysa mid ku habboon in loo isticmaalo codsiyada halkaasoo heer sare oo waxtarka sifaynta looga baahan yahay.

Cuntada iyo Cabitaanka

Shaandhooyinka birta la shiiday ayaa sidoo kale loo isticmaalaa cuntooyin iyo cabitaano kala duwan, oo ay ku jiraan sifaynta biirka, khamriga, iyo cabitaannada kale. Waxay si gaar ah faa'iido ugu leeyihiin codsiyada halka heer sare oo waxtarka shaandhaynta loo baahan yahay, iyo halka shaandhada ay tahay inay u adkeysan karto heerkulka sare iyo bay'adaha daxalka.

Haddii aad u baahan tahay badeeco shaandhayn ah oo buuxinaysa shay gaar ah, cabbir, ama shuruudaha codsiga, fadlan xor u noqonala soo xidhiidhsi aad uga hadasho baahiyahaaga.

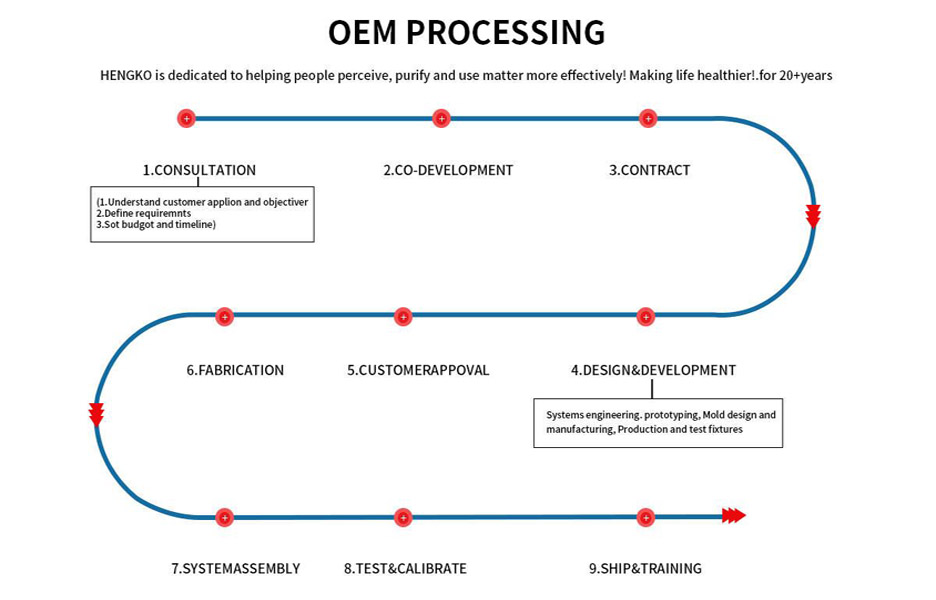

Habbee habka shaandhaynta birta sintered

Ku soo dhawoow inaad qaadato shaandhada shuruudaha naqshadaynta gaarka ah si aad nala soo xidhiidho, waxaanu u heli doonaa xalka shaandhada ugu fiican

shuruudaha shaandhaynta. iyowaxaad raaci kartaa hanaan dhameystiran si aad u hubiso in badeecada ugu dambeysa ay la kulanto

dhammaan tilmaamaha lagama maarmaanka ah. Habka waxaa ka mid ah:

1.La-tashi iyo La xidhiidh HENGKO

2. Horumarka wada jirka

3. Heshiis la gasho

4. Naqshadeynta & Horumarinta

5. Oggolaanshaha Macaamiisha

6. Wax-soo-saarka/Waxsoosaarka Guud

7. Nidaamka nidaamka

8. Tijaabi & Calibrate

9. Rakibaadda & Rakibaadda

Haddii aad u baahan tahay badeeco shaandhayn sinteed ah oo buuxisa shay gaar ah, cabbir, ama shuruudaha codsiga,

fadlan nala soo xiriir si aan uga hadalno baahiyahaaga.

Maxaa ka soocay HENGKO Warshadaha Sifaynta Birta ee Sintered?

Waa maxay sababta ay u doorato filtarrada birta ee sintered ee HENGKO?

filtarrada biraha sintay ee HENGKO ayaa macaamiisheena aad ugu tixgaliyaan awoodooda wasakhda ah ee gaarka ah iyo cimrigooda dheer.

Lagu soo saaray hab si fiican loo xakameeyey, filtarradan OEM Sintered Metal filtarrada waxay bixiyaan daloolo si siman loo qaybiyey.

oo leh qiimeeyn micron ahu dhexeeya 0.1μ to 100μ, hubinta sifeyn sax ah oo la isku halayn karo.

Faa'iidooyinka muhiimka ah ee filtarrada birta la shiiday ee HENGKO:

1. Naqshad xasiloon oo waara:

Shaandheeyayaashayagu waxay ilaaliyaan qaab deggan oo leh iska caabin aad u wanaagsan oo saamaynaya iyo culaysyo beddela,

iyaga oo ka dhigaya kuwo aad u waara xitaa marka lagu jiro xaalado adag.

2. Permeability Hawada Sare:

Iyada oo hufnaanta sifaynta joogtada ah, filtarradayada birta ah ee sintered waxay bixiyaan hawo aad u fiican,

hubinta waxqabadka ugu fiican ee codsiyada kala duwan.

3.Awood sare iyo iska caabin daxalka:

Naqshadeynta si ay ugu adkeysato cadaadiska sare iyo jawiga daxalka badan, filtarradayadu waxay bixiyaan xoog dejin gaar ah,

iyaga oo ka dhigaya kuwo ku habboon dalabka goobaha warshadaha.

4.Waxqabadka Heerkulka Sare:

Si gaar ah ugu habboon sifaynta gaaska heerkulkiisu sarreeyo,

filtarradayada birta ah ee sintered ayaa si la isku halleyn karo ugu shaqeeya deegaan aad u daran.

5.Ikhtiyaarada Habaynta:

Waxaan bixinaa xalal la habeeyey oo leh qalabyo kala duwan, qaabab, iyo cabbirro isku xidhidh si loo daboolo baahiyaha codsi ee gaarka ah.

Sida soo saaraha sumcadda leh ee Shiinaha, HENGKO waxay ku takhasustay soo saarista filtarrada birta ah ee casriga ah.

Kooxdayada farsamoyaqaannada xirfadlayaasha ah waxay u heellan yihiin horumarinta iyo soo saarista waxqabad sare

birta aan la taaban karin iyo walxaha daloola

Si sharaf leh loogu aqoonsaday shirkad tignoolajiyadeed sare leh, HENGKO waxay iskaashi la samaysaa jaamacadaha hormuudka ka ah labadaba gudaha

iyo caalami ahaan si joogto ah u cusboonaysiinta iyo horumarinta alaabtayada.

4-Talooyin Marka la dooranayo & Sifeynta birta ee OEM Sintered ee ay tahay inaad daryeesho

Waxaa jira dhowr siyaabood oo loo habayn karo filtarrada birta ah ee sinteed si loo buuxiyo shuruudaha codsiga gaarka ah.

Qaar ka mid ah hababka caadiga ah waxaa ka mid ah:

1. Doorashada birta ku habboon:

Biraha kala duwani waxay leeyihiin sifooyin kala duwan oo saamayn karawaxqabadka ee

shaandhada birta ah ee sintered. Tusaale ahaan, birta aan daxalka lahayn ayaa u adkaysata daxalka waxayna leedahay meel dhalaalkeedu sareeyo, halka

aluminiumku wuu fudud yahay wuxuuna leeyahay korantada wanaagsan.

2. Sheegidda cabbirka daloolka iyo qaabka:

Shaandhooyinka birta ah ee la jeexjeexay waxaa lagu naqshadayn karaa daldaloolo cabbirro kala duwan leh iyo

qaabab ku habboon baahiyaha kala duwan ee shaandhaynta. Tusaale ahaan, shaandhada leh daloolo yaryar ayaa wax ku ool u noqon doona in meesha laga saaro

Qaybaha yaryar, halka shaandhada leh daloollada waaweyni ay aad ugu habboonaan karto heerarka socodka sare.

3. Beddelidda dhumucda shaandhada:

Dhumucda warbaahinta shaandhada ayaa sidoo kale lagu hagaajin karaa si gaar ah

shuruudaha codsiga. Warbaahinta dhumucdeedu waxay bixin kartaa hufnaan sifeyn weyn laakiin waxay sidoo kale keeni kartaa sare

cadaadiska hoos u dhaca iyo heerka socodka oo yaraada.

4. Hagaajinta heerkulka iyo xaaladaha cadaadiska:

Shaandhooyinka birta ah ee la jeexjeexay ayaa loo qaabayn karaa si ay u adkaystaan gaar ah

heerkulka iyo xaaladaha cadaadiska, taas oo ku xidhan codsiga. Waa muhiim in la tixgeliyo arrimahan marka

doorashada filtarrada si loo hubiyo in ay u adkeysan karto shuruudaha hawlgalka nidaamka.

Si aad u habayso shaandhada birta ah ee sintay si ay u buuxiso shuruudahaaga gaarka ah, la tashanaya injineer khibrad leh

ama khabiir farsamo oo goobta jooga ayaa ku caawin kara. Waxay hagi karaan naqshadda ku habboon iyo xulashada alaabta ku salaysan

shuruudaha codsiga gaarka ah.

FAQShaandhooyinka birta ee Sintered

1. Waa maxay shaandheynta birta la shiiday?

Qeexitaan gaaban oo shaandhada birta ah ee sintay:Waa filtar bir ah oo adeegsata walxaha budada birta ah ee cabbirka isku midka ah

in lagu qaabeeyo shaabad, heerkul sare oo sintering ah waa habka birta iyadoo la isticmaalayo cabbirka budada ah.

jirka biraha kala duwan iyo Alloys ka dib shaabadeynta.

Metallurgy waxay ku dhacdaa fidinta heerkulka ka hooseeya barta dhalaalka ee foornooyinka heerkulka sare leh. Biraha iyo Alloysyada

Sida caadiga ah maanta loo isticmaalo waxaa ka mid ah aluminium, copper, nikkel, bronze, ahama, titanium.

Waxaa jira habab kala duwan oo aad isticmaali karto si aad u sameysid budada. Waxay ka mid yihiin shiidi, automation, iyo kala-goynta kiimikada.

Faahfaahin dheeraad ah oo ku saabsanWaa maxay shaandhada birta ee Sintered, fadlan tag oo hubi maqaalkan.

2. Maxay tahay sababta loo isticmaalo birta aan-xawaaraha lahayn si loo sameeyo shaandhayn?

Si aad u dooratid birta aan birta lahayn sida alaabta ugu muhiimsan, sababtoo ah waxay leeyihiin faa'iidooyin badan oo birta ah

1. Ma fududa daxalka

2. Heerkulka qulqulaya uma baahna inuu aad u sarreeyo

3. Daloolada waa sahlan tahay in la xakameeyo inta lagu guda jiro sintering

4. Naqshadeynta sintered waa ka sii waarta oo ma fududa in la habeeyo

5. fududahay in la nadiifiyo

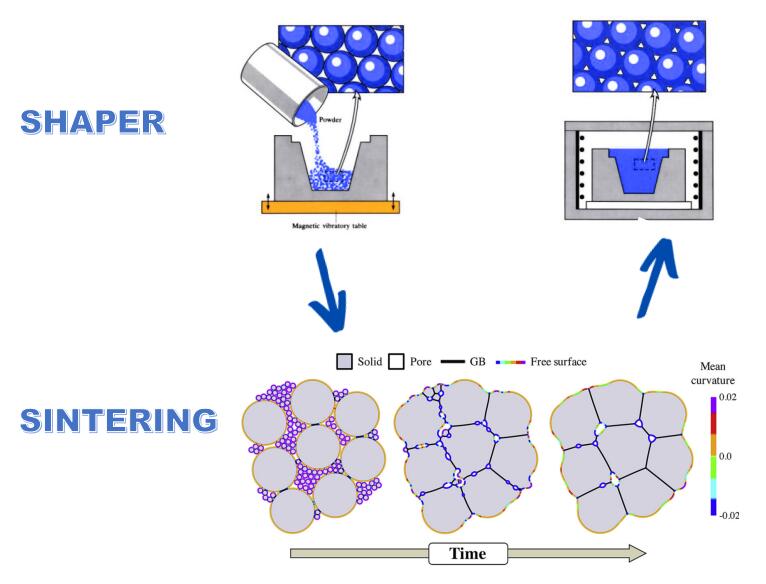

3. Sidee loo Sameeyaa Shaandheeyaha Birta La Dajiyay?

Habka wax soo saarka ee shaandhada birta Sintered, ugu weyn waxay leeyihiin 3-tallaabo sida soo socota:

J: Talaabada ugu horeysa waa in la helo birta korontada.

Budada birta ah, Waxaad ku heli kartaa budada birta adigoo shiidi, otomaatig ah, ama kala go'a kiimikaad. Waxaad isku dari kartaa hal bir ah

budo leh bir kale si aad u sameysid daawaha inta lagu jiro habka wax-soo-saarka, ama waxaad isticmaali kartaa hal budo oo keliya. Faa'iidada sintering waa taas

ma beddelo sifooyinka jireed ee walxaha birta ah. Nidaamku aad buu u fudud yahay in walxaha birta ah aan la beddelin.

B: Shaabadeynta

Talaabada labaad waa in lagu shubo budada birta ah caaryada hore loo sii diyaariyay taas oo aad ku qaabayn karto shaandhada. Isku-xidhka shaandhada ayaa lagu sameeyay qolka

heerkulka iyo hoos shaabadeynta. Qadarka cadaadiska la saaray wuxuu ku xiran yahay birta aad isticmaalayso, maadaama biraha kala duwan ay leeyihiin dabacsanaan kala duwan.

Ka dib marka uu saameyn ku yeesho cadaadiska sare, budada birta ah ayaa lagu dhejiyaa caaryada si ay u sameeyaan filtar adag. Ka dib habka saameynta cadaadiska sare, waad awoodaa

Geli filtarka birta ah ee diyaarsan foorno heerkul sare leh.

C: Heerkulka sare ee sintering

Geedi socodka sintering, qaybaha biraha waa la isku daray si ay u sameeyaan hal unug oo aan la gaarin barta dhalaalaysa. monolithkan ayaa u xoog badan

filtar adag, oo daloola sida birta oo kale.

Waxaad ku koontarooli kartaa porosity shaandhada habka iyadoo loo eegayo heerka socodka hawada ama dareeraha la sifeynayo.

4. Waa maxay Habka Sintering?

Hal talaabo oo muhiim ah waa Sintering, markaa waa maxay habka loo maro sinta iyo in la noqdo filtarrada birta ah?

Waxaad u eegi kartaa sida shaxda soo socota si aad si cad u fahanto.

5. Waa maxay Tilmaamaha ugu Muhiimsan ee Shaandheynta Birta La Siintered?

Ka dib habka shaabadeynta iyo heerkulka sare ee sintering, waxaan heli karnaa filtarrada biraha sintered, ka dibna gudaha

si aan u ogaano tayada filtarrada sinteed, sida caadiga ah, waxaanu tijaabin doonaa qaar ka mid ah xogta filtarrada, haddii xogtu gaadho

Shuruudaha sida ay macaamiishu weydiiyeen, ka dib waan sii deyn karnaa si aan u diyaarino dhoofinta.

1. Porosity

2. Tijaabada cadaadiska

3. Tijaabada socodka (gaaska iyo dareeraha)

4. Tijaabada buufinta milixda (baaritaan ka hortagga miridhku)

5. Cabbirka muuqaalka cabbirka

Haddii aad weli jeceshahay inaad wax badan ka ogaatomabda'a shaqada filter sintered, fadlan eeg faahfaahinta hubinta blog-kan.

B:Codsigaee Sintered Metal Filter

6. Aaway Codsiga Shaandhooyinka Birta Dabiiciga ah?

Sida macaamiisheena u tixraaco qaar ka mid ah codsiga muhiimka ah ee filter-ka sinteed sida soo socota:

1.) Sifeynta dareeraha2. dareere

3. Daboolista4. Faafin

5. Qabta Ololka6. Sifeynta Gaaska

7. Cuntada iyo Cabitaanka

7. Ma isticmaali karaa miirayaasha birta la shiiday oo leh noocyo badan oo saliid ah?

Haa, laakiin waxay u baahan yihiin in la habeeyo cabbirka daloolka gaarka ah sida saliidda, sidoo kale shuruudaha xakamaynta socodka, sidaas darteed

waad ku soo dhaweyn kartaanala soo xidhiidhsi aan u ogaano faahfaahintaada.

8. Shaandheeyaha birta la shiiday ma sii shaqayn karaa xitaa marka ay xaaladuhu barafoobaan?

Haa, shaandhada birta ee sintered, sida 316Lshaandhada birta aan lahayn sinteredhoos shaqayn kara

-70 ℃ ~ +600 ℃, sidaas darteedInta badan shaandhada sintered waxay ku shaqayn kartaa qaboojinta. laakiin loo baahan yahay in la hubiyo

Dareeraha iyo gaasku waxay ku qulquli karaan xaaladda qaboojinta.

9. Nooc noocee ah ayaa Kiimikada lagu shaandhayn karaa Shaandhooyin Bir ah oo Wasakhaysan oo aan waxyeello u gaysanayn Jirka Filterka?

Waxaan tijaabineynaa inta badan kiimikooyinka lagu dhex wareejin karo alaabtan gaarka ah iyada oo aan waxyeello loo geysan,

sida phenol marka loo eego in lagu sameeyay iyadoo la isticmaalayo walxo u adkaysta kiimikaad.

1. ) Asiidh

Asiidhyo adag: waxaa ka mid ah sulfuric acid (H2SO4), nitric acid (HNO3), iyo hydrochloric acid (HCl).

Asiidh daciif ah oo ku jira uruurin sare, sida acetic acid

Xalalka aashitada B Lewis oo leh sifooyin kiimiko oo gaar ah, sida zinc chloride

2.) Saldhigyo Adag:

oo ay ku jiraan sodium hydroxide (NaOH) iyo potassium hydroxide (KOH)

Biraha Alkali (sida sodium) ee xaaladdooda macdanQalabka birta ah ee alkaline iyo alkaline

Heerarka sare ee saldhigyada daciifka ah sida ammonia

3.) Walaxaha fuuq baxa.

oo ay ku jiraan sulfuric acid, fosfooraska pentoxide, calcium oxide,

zinc chloride (aan xal ahayn), iyo walxaha birta ah ee alkali

4.) Waxyaalaha oksaydhiyeyaasha xooggan,

oo ay ku jiraan hydrogen peroxide, nitric acid, iyo sulfuric acid.

5.) Halogenyada korantada

sida fluorine, chlorine, bromine, iyo iodine (ions of halides maaha kuwo daxaloobay),

iyo cusbada korantada sida sodium hypochlorite.

6.) Halides organic ama halides of organic acids, sida acetyl chloride iyo benzyl chloroformateanhydride

7.)Wakiilada Alkylatingsida dimethyl sulfate

8.) Qaar ka mid ah xeryahooda organic

10. Sidee loo Nadiifiyaa Shaandhooyinka Birta Dabiiciga ah?

Nadiifinta saxda ah waa lagama maarmaan si loo ilaaliyo waxqabadka iyo cimri dhererka filtarrada birta ah ee sintay.

Iyada oo ku xidhan codsiga-haddii sifaynta gaaska ama dareeraha-habab nadiifin oo kala duwan ayaa la adeegsan karaa:

1. Dib u dhac ku yimaada Codsiyada Gaaska:

*Nidaamka sifaynta gaaska, dib-u-celinta waa hab caadi ah oo loo isticmaalo in lagu nadiifiyo filtarrada birta jeexan.

Habkani waxa uu ku lug leeyahay dib u celinta qulqulka gaaska ee soo dhex mara shaandhada, kala daadinta walxaha xayiran,

iyo nadiifinta warbaahinta shaandhada.

2.Backflush for Liquid Applications:

* Nidaamyada sifaynta dareeraha ah, dib-u-soo-celinta waa hab nadiifin oo waxtar leh. Habkani waxa uu beddelaa qulqulka dareeraha ee shaandhada si uu meesha uga saaro wasakhda urursan oo uu u soo celiyo waxqabadka shaandhada.

3.Nadiifinta Ultrasonic:

* Nadiifinta ultrasonic waxaa loo isticmaalaa in laga saaro walxaha kiimikaad ahaan aan shaqayn ee shaandhada. Habkani waxa uu adeegsadaa mowjadaha dhawaaqa soo noqnoqda si ay u abuuraan goobooyin yar yar oo xal nadiifin ah, kaas oo si wax ku ool ah u daadiya ugana saaraya wasakhda dusha shaandhada.

4.Nadiifinta Kiimikada:

Si meesha looga saaro wasakhda qallafsan, hababka nadiifinta kiimikada ayaa la adeegsan karaa. Kuwaas waxaa ka mid noqon kara:

*Nadiifinta dareeraha:

Isticmaalka dareerayaasha ku habboon si loo milo loogana saaro wasakhowga dabiiciga ah.

*Dhaqidda Kaustikada:

Isticmaalka xalalka alkaline si loo burburiyo loogana saaro walxaha organic iyo kuwa aan noolaha ahayn.

*Asiidh dhaqid:

Xalalka acidic ayaa loo isticmaalaa in lagu milo kaydadka macdanta ama oksaydhyada.

Biyaha iyo Qulqulka Hawada:

Isku darka biyaha iyo daadinta hawada ayaa loo isticmaali karaa in meesha laga saaro hadhaaga iyo in la hubiyo in shaandhada si fiican loo nadiifiyo.

Hababkan nadiifinta ayaa gacan ka geysanaya kordhinta nolosha filtarrada birta ah ee sintay, hubinta inay sii wadaan bixinta waxtarka leh

iyo sifaynta lagu kalsoonaan karo ee codsiyada kala duwan.

C:Macluumaadka DalabkaShaandheeyaha Birta la shiiday

10. Ma beddeli karaa shaandhada birta ah ee sintay marka laga dalbanayo HENGKO?

Haa, hubaal .

Waxaan u awoodnaa OEM Sintered Metal Filters sida liiska shuruudaha soo socda:

1. Cabbirka daloolka

2. Qiimaynta Micron

3. Heerka socodka

4. Shaandhayso warbaahinta aad isticmaali doonto

5. Cabbir kasta sida naqshaddaada

11. Waa maxay MOQ ilaa Jumlo shaandhaynta birta sintered ee HENGKO?

Haddaanu nahay Soo-saare Shaandheeyayaal Xirfad-yaqaan ah, waxaanu leenahay nooc ka mid ah ikhtiyaarka sida Sintered Filters Disc,

Tube Filters Sintered,Taarikada Shaandhaynta Sintered, Koob Filters Sintered,Shaandheynta Shaandheynta Sintered, Ku Saabsan MOQ-ga

ku salaysnaan doonocabbirka naqshadeynta iyo cabbirka daloolka iwm, caadi ahaan MOQ-keena waxay ku saabsan tahay 200 -1000pcs / shay ku saleysan naqshadeynta.

12. Maxaa ka dhigaya filtarrada birta jeexjeexan ee HENGKO mid gaar ah?

1.) filtarrada biraha sintered HENGKO waxaa lagu kala soocaa isticmaalkafarsamooyinka lahaanshaha

taas oo dammaanad qaadaysa cabbirrada daloolka joogtada ah iyo hufnaanta qaabdhismeedka gaarka ah.

2.) Waxaa intaa dheer, HENGKO waxay bixisaa ballaaranikhtiyaarada habaynta, taasoo u oggolaanaysa macaamiishu inay ku tolan karaan

porosity, alaabta, iyo naqshadeynta si ay ugu habboonaato baahidooda codsi ee gaarka ah.

Daraasad Kiis:

1. Iftiinka Daraasadda Kiis:Sifeynta Gaaska Warshadaha

Waxqabadka La Wanaajiyey ee Sifeynta Gaaska Warshadaha oo leh Shaandhooyin Bir ah oo La Habeeyey

Loollan:

Warshada warshadaynta gaaska warshaduhu waxay la kulantay arrimo hoos u dhac ku yimid hufnaanta nidaamka sifaynta,

taasoo keenaysa dayactir joogto ah iyo waqti aan la filayn.

Shaandhooyinka jira waxay awoodi waayeen inay xamili waayeen culayska walxaha sare, taasoo keentay xidhidh iyo hoos u dhac heerarka socodka.

Xalka:

Khubarada HENGKO waxay ku taliyeen in filtarrada jira lagu beddelo shaandhada birta sinteed loo qaabeeyey oo ku habaysan

codsiyada load qayb sare. filtarradani waxay soo bandhigeen qaab dhismeedka daloolka la hagaajiyay iyo adkaysiga la xoojiyay,

si gaar ah loo farsameeyay si uu u maareeyo baahida sifaynta gaaska warshadaha.

Natiijada:

Shaandhooyinka cusub ee biraha la jeexjeexay ayaa si aan kala go 'lahayn loogu dhex daray nidaamka jira, taas oo si weyn u yaraysay xidhmidda

arrimaha iyo inta jeer ee dayactirka.

Shaandhooyinka la hagaajiyay ayaa bixiyay 30% korodhka heerka socodka iyo kor u qaadista waxqabadka nidaamka guud.

Iyadoo la qaadanayo filtarrada birta sintered ee caadiga ah ee HENGKO, warshadda gaaska warshaduhu waxay la kulantay calaamad

hagaajinta hufnaanta sifaynta, cimriga filtarka oo la dheereeyey, iyo hoos u dhaca shaqada.

Xalku kaliya ma wanaajin wax soo saarka laakiin waxa kale oo uu gacan ka gaystay hawl-gal kharash-ku-ool ah iyada oo la yareynayo

kharashyada dayactirka iyo hubinta waxqabadka nidaamka aan kala go'a lahayn.

Wali Su'aalo Hayso oo Jecel in aad Faah Faahin Dheeraad ah Ka OgaatoShaandheeyaha Birta la shiidayFadlan xor u noqo inaad nala soo xidhiidho hadda.

Sidoo kale waad awoodaaEmail noogu soo dirToos sida soo socota:ka@hengko.com

Waxaan ku soo celin doonaa 24-saacadood, Waad ku mahadsan tahay Bukaan-socodkaaga!