Budada birta ah ee daloola ee la miiray birta aan-axinka lahayn ee shaandhaynta soo kabashada ee habka soo kabashada

Hordhac kooban oo ku saabsan mabda'a shaqada ee shaandhada shaandhaynta (miirayayaasha la isku xidhay) qalabka: HENGKO Sintered Metal Catalyst Filter waxay isticmaashaa kicinta si ay u soo kabsato una nadiifiso.Waxaan ognahay in kicinayaashu ay ku jiraan meel aad muhiim u ah warshadaha kiimikada casriga ah.Marka loo eego tirakoobyada, qiyaastii 80% ilaa 85% ee hababka wax soo saarka kiimikaad waxay isticmaalaan kicinta si ay u dedejiyaan heerka falcelinta oo ay u wanaajiyaan waxtarka wax soo saarka.

Hordhac kooban oo ku saabsan mabda'a shaqada ee shaandhada shaandhaynta (miirayayaasha la isku xidhay) qalabka: HENGKO Sintered Metal Catalyst Filter waxay isticmaashaa kicinta si ay u soo kabsato una nadiifiso.Waxaan ognahay in kicinayaashu ay ku jiraan meel aad muhiim u ah warshadaha kiimikada casriga ah.Marka loo eego tirakoobyada, qiyaastii 80% ilaa 85% ee hababka wax soo saarka kiimikaad waxay isticmaalaan kicinta si ay u dedejiyaan heerka falcelinta oo ay u wanaajiyaan waxtarka wax soo saarka.

Dib-u-warshadaynta dib-u-warshadaynta dab-damisku waxa ay noqdeen lagama-maarmaan, gaar ahaan kuwa biraha ka shaqeeya.Filter-ka HENGKO waa soo kabashada iyo nidaamka nadiifinta ee soo kabanaya kicinta iyada oo loo marayo sifaynta tooska ah iyo xoojinta, kala-soocidda magnetka, sifaynta wanaagsan, iyo kala-soocidda xuubka.Faa'iidooyinka dhaqaale ee filtarrada HENGKO waa

1. Yaraynta khasaaraha alaabta qaaliga ah

2. Hagaajinta tayada alaabta

3. Yaraynta dheecaanka qashinka iyo buuxinta heerarka deegaanka cagaaran

4.Yaree wareegga dayactirka iyo kharashka

5.Yaree isticmaalka tamarta

6. Hagaajinta heerka soo kabashada iyo heerka nadiifinta

Kala soocida dhaqameed ee qallafsan ee kicinta guud ahaan waxay isticmaashaa taangiyada biyaha lagu dhaqo ama filtarrada faakuumka.Qalabkani waa mid qiimo jaban wuxuuna ku fadhiyaa dhul ballaaran.Maalintii meesheeda shaandhayntu waa mid toosan.Dhumucda keegga oo aan sinnayn, fududahay in la dilo, ma fududa in la dhaqo, ay adag tahay in la shaandheeyo, ay adag tahay in la shaandheeyo, maro shaandhayso si degdeg ah ayay u xidhan tahay, oo ay fududahay in la xannibo, aad u dhib badan in la isticmaalo, ka shaqaynta xawaaraha dejinta ma aha mid sarreeya, waqti badan iyo shaqo qaadanaysa si weyn u kordhinaya wadarta kharashka maalgashiga.Marka la barbar dhigo qalabka farsamaynta dhaqameed, filtarrada birta ah ee kooxdu waxa loo isticmaali karaa gaas guban kara iyo kuwa qarxa, budada jidhka sunta ah, qaybaha jilicsan, adkaha qallafsan, sifaynta nuxurka adag, iyo awoodda haynta wasakhda sare, oo gebi ahaanba ah qalabka centrifugal, qalabka qalajinta isticmaalka qalabka hore ee marxaladda.

Mabda'a shaqada:

Dareeraha walxaha leh kiciye waxay ka soo galaan meel ka baxsan shaandhada sintay waxayna u sii maraan walxaha shaandhada dibadda ilaa gudaha.Wasakhda ka weyn godadka shaandhada ayaa dhexda lagu xiraa oo ku urura dusha walxaha shaandhada si ay u sameeyaan keega shaandhada.Isku xirka, keega filtarku wuxuu qabsan karaa qaar ka mid ah wasakhda ugu fiican biyaha.Marka ay wasakhdu ku ururto ilaa xad, cadaadiska kala duwani wuxuu kor u kacaa qiimaha nidaamka, soo dejinta iyo dhoofinta dareeraha dareeraha ayaa xira, gaaska ciriiriga ah ayaa soo galaya oo engejiya keega filter.Wasakhda gaaska dib-u-qabashada ayaa lagu sii daayaa habka dib-u-qarxinta, iyo kartoonada shaandhada ayaa dib loo soo cusbooneysiiyay.

Sharaxa Alaabta

Nidaamka sifaynta birta dalool ee Micron waxaa loo isticmaalaa in batroolka iyo hababka wax soo saarka kiimikaad ee dhammaan dareeraha-adag iyo gaaska-adag kala soocidda waxtarka sare leh, xudunta u ah taas oo ah budada birta sintered element biraha microporous, sida caadiga ah ka samaysan316L oo ah budada birta ah, Hastelloy, titanium, iwm filter biraha dalool Tani waxay la qabsan kartaa heerkulka habka sare iyo cadaadiska ee sifaynta iyo dhirta kiimikada, iyo in la hubiyo saamaynta sifaynta iyadoo la gaarayo cadaadiska ugu yar ee hoos u dhaca iyo heerka dib u dhaqidda ugu badan.

Nidaamka sifaynta birta dalool ee Micron ee wax soo saarka petrochemical waxay leedahay sifooyinka caabbinta heerkulka sare, hoos u dhigista cadaadiska sare, hawlgalka nuxurka adag;dareeraha (gaaska) iyo kala-soocidda waxtarka sare ee adag;nidaamka dib-u-dhaqidda gudaha si looga saaro adkaha;hawlgal toos ah oo toos ah;sidoo kale waxay ka fogaan kartaa beddelaad joogta ah iyo tuurista walxaha shaandhaynta wasakhowga deegaanka.

Codsiyada:

Soo kabashada budada birta ah ee qaaliga ah iyo kicinta birta qaaliga ah

CTA, PTA, iyo nidaamka soo kabashada ee wax soo saarka PTA

Dhuxul ilaa olefin (MTO) nidaamka soo kabashada kicinta

Sifaynta dareeraha saliidda iyo saliidda wareegaysa ee qaybta dildilaaca

Nadiifinta gaasta qiiqa dib u soo kabashada iyo unugga xakamaynta siigada

Nidaamka sifaynta saliidda Feedstock ee habka hydrogenation/coking sifaynta

Nidaamka sifaynta kicinta ee Raney Nickel (Raney Nickel) habka hydrogenation

Shaandhaynta gaaska nadiifka sare leh ee waferka, warbaahinta kaydinta, habka wax soo saarka wareegga isku dhafan

Bandhiga Alaabta

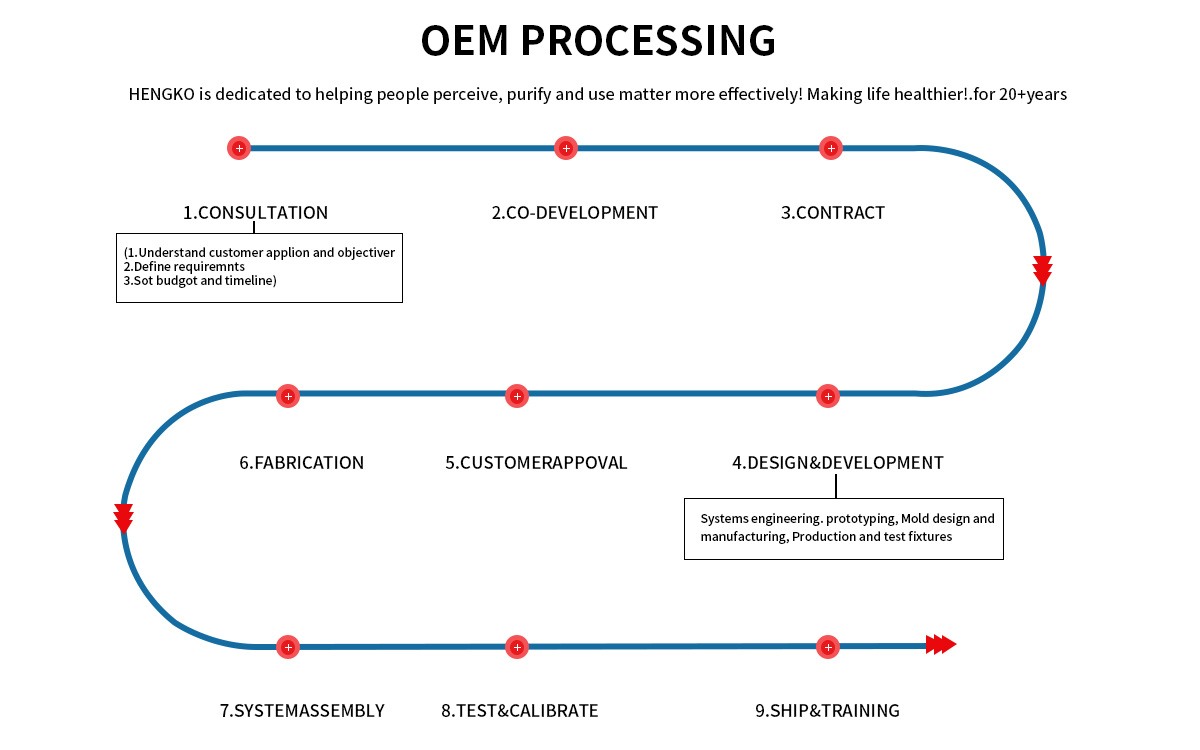

Miyaadan heli karin badeecad daboolaysa baahiyahaaga?Kala xidhiidh shaqaalahayada iibkaAdeegyada wax-ka-beddelka OEM/ODM!

Miyaadan heli karin badeecad daboolaysa baahiyahaaga?Kala xidhiidh shaqaalahayada iibkaAdeegyada wax-ka-beddelka OEM/ODM!